Lowa Sportschuhe GmbH is a German footwear company, known primarily for its climbing shoes sought after for their uncompromising quality. However, shoes for regular tourists are also popular, of which Lowa offers several, and which are also among the top on the market.

Lowa Sportschuhe GmbH is a German footwear company with a very rich history. Currently, it is part of the TECNICA GROUP holding, in which LOWA represents the strongest brand. The company focuses primarily on hiking (trekking) shoes, military and sports shoes, and its climbing boots are very well known. It is a large and significant company exporting worldwide, and in Europe, it is one of the largest manufacturers of trekking shoes.

Origins of the Company

The history of the company begins in 1923, when Johann Wagner operated a shoemaking workshop in the Bavarian village of Jetzendorf. His son Lorenz Wagner continued in his father's footsteps, expanding and modernizing the production, and took over the leading role in the company, which later began to bear his name: LOWA = Lorenz Wagner

In the early 1930s, Wagner built a new factory building, where true industrial production started. After Hitler came to power in 1933, the Jetzendorf factory received a contract to produce heavy footwear for mountain hunters. After the war, however, the situation was very unfavorable and the company found itself in a difficult position, but the demand for footwear allowed the company to survive. After 1950, the situation deteriorated dramatically, the company became insolvent and went into forced administration. Lorenz Wagner was greatly affected by this and, with his failing health, died in his 60s.

Sepp Lederer

In difficult times, the company was taken over from the ailing Wagner by Sepp Lederer, whom Wagner himself had trained in his workshops, and who together with Wagner's daughter Berti tried to stabilize the company. They gradually succeeded and together they led the company out of a dead-end situation. Later they became husband and wife.

From 1955 onwards, better times began for Lowa. The company started close cooperation with leading climbers and, thanks to the gained experience, developed very sophisticated shoes for that time. Gradually, Lowa became a world-renowned name in climbing footwear.

The company's growth required new premises. Initially, they used whatever space was available, but later a new complex in Jetzendorf was constructed, completed in 1977. As the company grew, the existing spaces became insufficient, and from 1998 to 2000 a completely new complex of buildings was built, which serves the company to this day.

Werner Riethmann

This top manager from the competing company Raichle accepted Sepp Lederer's offer and took over the leadership of LOWA with the task of reviving stagnant sales. This proved to be the right move, Riethmann led the company well and it became one of the largest producers of trekking footwear. Later, capital strengthening of the company was undertaken, becoming part of the Tecnica holding. Under Werner Riethmann's leadership, LOWA successfully celebrated 90 years of its existence. Its strategic focus on top-quality attributes with an emphasis on comfort and usability continues to be successful among all demanding users.

WORK AND SAFETY FOOTWEAR

First, let's discuss the differences between testing work and safety footwear.

In the case of work footwear, emphasis is placed on testing durability in constant work conditions. These tests can reveal, for example, how the sole resists abrasion, how stable the sole is at low temperatures, how non-absorbent the materials used are, and how resistant the shoe is when in contact with mineral oils or fuels.

The assessment of safety footwear depends on how well the toe is protected against the fall of heavy objects, how the foot is protected against sole perforation by a nail, what the electrical insulating properties are, and similar factors.

In both cases, special additional tests are often carried out to determine, for example, whether the footwear protects against water penetration inside the shoe, how slip resistance works on various surfaces, and so on. If the footwear passes these additional special tests, it is marked with special written symbols.

Work footwear is defined by the EN ISO 20344 and EN ISO 20347 standards. The first of these standards indicates that the footwear has basic requirements that any work footwear must meet. The second standard indicates that the shoe boasts several excellent features and can be used for other specialized work fields. Many of these conditions required by the standards are met, for example, by robust outdoor footwear from the LOWA BACKPACKING category and of course, also by military models from the LOWA TASK FORCE collection.

Furthermore, we also classify work footwear into several additional categories based on test results:

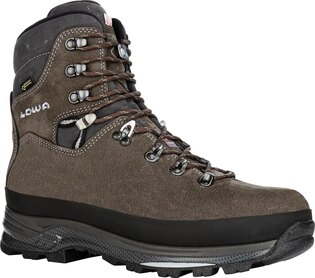

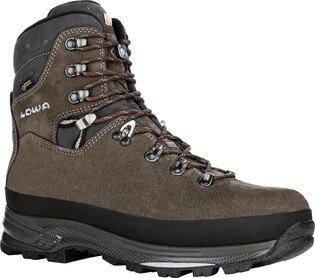

The OB category, specifically EN ISO 20347 OB, includes footwear that meets basic requirements according to EN ISO 20344, specifically the durability of the sole, which is resistant to abrasion. This category includes, for example, outdoor footwear from the BACKPACKING category, specifically the TIBET GTX model, which also meets the requirements for non-absorbency, resistance to water penetration, sole durability at low temperatures, and slip resistance even on wet ceramic surfaces. These additional features are also marked by symbols WR, CI, SRA, which are explained in a few lines below.

A higher category is considered 01, which is precisely marked EN ISO 20347 01, where it is required that the heel area is enclosed, the shoe has antistatic properties, and an adequate level of shock absorption in the sole and heel.

Further, category 02 with the designation EN ISO 20347 02 must absolutely meet the requirements of the previous category 01, but in addition, the shoe must be resistant to water penetration and must possess the water-repellent properties of the upper material.

Finally, we have category 03 with the designation EN ISO 20347 03, which must provide protection against sole perforation by a nail. This category mostly includes work footwear intended for construction sites.

Of course, there are other combinations of features, and the description of these basic categories may not be sufficient. Therefore, we attach additional symbols indicating supplementary criteria:

HRO - resistance of the sole to contact heat

WRU - water penetration and absorption (upper material)

WR - resistance of the footwear to water penetration

HI - resistance of the footwear bottom to heat

CI - resistance of the footwear bottom to cold

FO - resistance of the footwear to fuel oils

AN - ankle protection

CR - cut resistance

M - resistance of the protective instep to impact

I - electrical insulating footwear

C- conductive footwear

P - resistance to penetration

E - energy absorption in the heel area

A - antistatic footwear

SRA- slip resistance on a ceramic tile floor with SLS /water solution/

SRB - slip resistance on a steel floor with glycerin

SRC - slip resistance on a ceramic tile floor with SLS and on a steel floor with glycerin /SRA + SRB/

Of course, there are categories of safety footwear according to the EN ISO 20345 standard. To give you an overview here as well, we again attach the categories with explanations:

EN ISO 20345 SB - basic requirements, e.g., steel toe cap, resistance to fuels, resistance to sole abrasion

EN ISO 20345 S1 – SB requirements + closed heel part + antistatic properties + energy absorption in the heel area

EN ISO 20345 S2 - like S1 + penetration + water absorption (upper material)

EN ISO 20345 S3 - like S2 + resistance to puncture + treaded outsole

Special is also the EN ISO 17249 standard, which can boast a condition for footwear protecting against chainsaw cutting.

In safety footwear, we can also encounter these abbreviations, which express additional criteria mentioned above in the text.

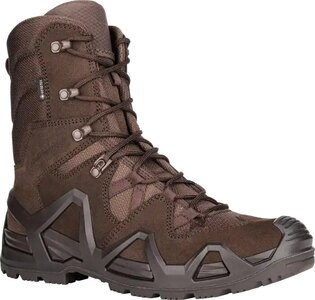

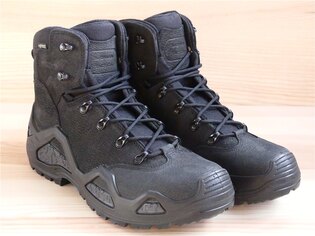

LOWA® Z‑8N GTX® C Boots

Lowa® 4 Seasons Pro socks

Lowa® 3 Season Pro socks

Lowa® Winter Pro socks

LOWA® Innox Pro GTX® MID TF Boots

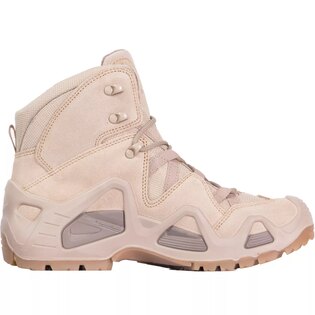

LOWA® Zephyr MID TF Ws Boots

LOWA® R‑8 GTX® Thermo boots ‑ black

LOWA® Renegade Evo Ice GTX Winter Shoe

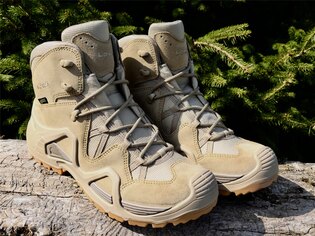

Zephyr MK2 GTX HI LOWA® Boots

LOWA® Shoe Care Brush

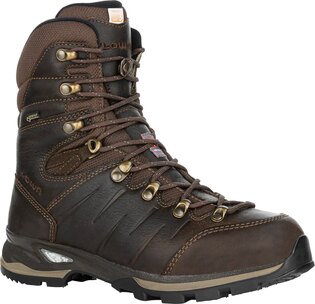

LOWA® Tibet GTX HI 200 Insulated Hunting Boots

LOWA® Yukon Ice II GTX Winter Shoes

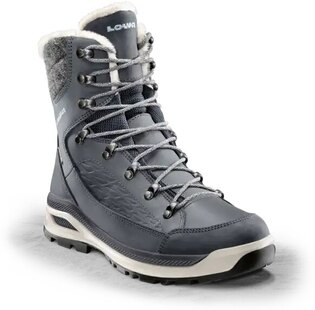

LOWA® Tibet Superwarm GTX Women's Shoes

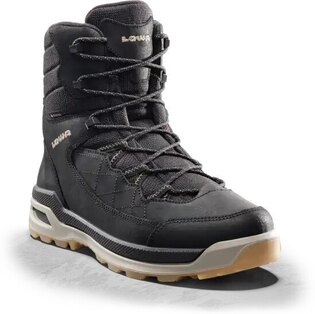

LOWA® Tibet Superwarm GTX Winter Shoes

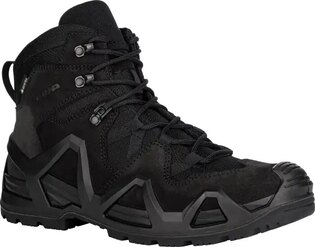

LOWA® Z‑6N GTX® C Shoes

Lowa® Laces 160 cm

LOWA® Active Cream 75 ml

Lowa® Laces 210 cm

Lowa® Laces 170 cm

Lowa® Laces 150 cm

Lowa® Laces 180 cm

LOWA® Renegade Evo Ice GTX Women's Shoes

Cold Weather Boots Ottawa GTX LOWA®

LOWA® Yukon Ice II GTX women's winter boots