The knife is one of the oldest companions of man. But are they all the same? Drop-Point, Spear-Point, Elmax, D2 and so on. What does it mean? We should know that before we start choosing a knife.

The steel blade embedded in the part called handle. Beautiful pouch and old love. Yes, we're talking about knives. Nowdays, an absolutely common thing that appears with more and more people. In the past it was a weapon or aid for life, mainly used for cutting, slicing and for work. The first forms of knives were formed in the Stone Age. Material used at that times were flints (flint stones). This form of quartz was due to its structure the most sought -after item for weapons. It was easy to work and created sharp edges that were perfect for the spikes of spears, arrows or blades of knives. Another material was copper, as in the Iron Age - Iron.

From flint to the steel

There were many materials that formed the knives. People tried and tried until they finally found the right material. Today they are steel alloys, very strong, hard with high corrosion resistance. What steel for my knife? Very interesting question. Unfortunately, there is no simple answer but little more complicated theories. Steel could be divided into bad ones, where we rank everything that is offered on markets and similar places. The better ones, ie good steels, are steels type AUS-8, AUS-6 or, for example, 9CR19MoV alloy. Such steel can be expected to have a good holding of the blade, a large strength and corrosion-resistance. If you are looking for the best in the category, it is a D2, A2 steel and others. These are knife makers steels , so they are sought after by professional knife makers. The knife of such a steel lasts for a life-time. So how do we know the good steel? Usually it is hard, we will have to find out the information ourselves. The only clue could be given by HRC hardness. If we are looking for a good knife, this hardness should not be less than 56. Of course the type of the knife is important too.

There is no knife like a knife

Perhaps even a small child knows that the knives can be divided into closing ones, with a fixed blade, multifunctional and so on. So can we use each of them for everything? Yes we can. But let's not expect it to last long. Like shoes, for example, there are knives with the exact designation for their use. For example, imagine that we would take a closing knife and start doing a hard work (cut branches, screw bolts etc.) with it. After while, we would have a blunt knife without tip or even broken one. Closing knives are rather backup knives. Perfectly fits into your pocket where they can wait. On the other hand, the knives with a solid blade have prerequisites for heavier work. Especially when it is the so -called Heavy Duty Knife. Such knives are made for work. In the pocket, in addition to the closing knife, we can find some of its multifunctional alternatives with screwdrivers, saws etc. And does it matter? Theoretically it doesn´t, we just have to count on buying knives more often than we would like.

Good grip = half victory!

We can have the best knife that keeps the blade perfectly and we don't have to be satisfied with it anyway. Ergonometry and handle material also play a role. The way the knife is shaped for our hand, it gives the comfort of working with the knife. As with steels, the handles also have their materials. Thanks to today's multi-material times, carbon fibers are widely used. They are ideal for work. They are elegant, firm and last long. On the other hand, nothing will look as elegant as wood that looks absolutely great in combination with metal. There are many possibilities and the choice is up to us. Let´s not rush it, so we are satisfied with the knife even in several years.

Cold Steel® Grik folding knife

Cold Steel® Kiridashi folding knife

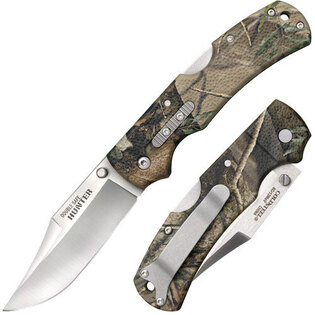

Cold Steel® Double Safe Hunter folding knife

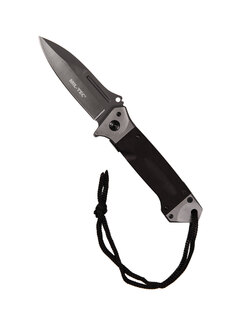

SOG® Escape FL folding knife

SOG® Terminus XR G10 folding knife

SOG® Terminus XR G10 Tini folding knife

SOG® Tellus ATK Orange folding knife

SOG® Tellus ATK Yellow folding knife

SOG® Adventurer LB folding knife

ANV® A100 Ultem BB folding knife

ANV® A200 Ultem BB folding knife

ANV® M06 GRN claw / wharncliffe knife

ANV® P250 fixed blade knife

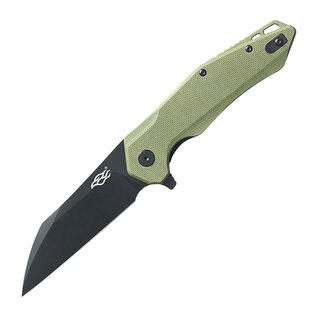

Ganzo® Firebird FH31B folding knife

Ganzo® G626 folding knife

Ganzo® G627 folding knife

Ganzo® G628 rescue folding knife

Ganzo® G704B folding knife

Ganzo® G707B switchblade knife

Ganzo® G721B switchblade knife

Ganzo® G770B folding knife

Ganzo® Firebird FH31 Carbon folding knife

Ganzo® G806 fixed blade knife