Steel 8Cr-Mo-V

8Cr - Mo – V steel is characterized by high hot strength above 1800 N/mm2 and very good toughness. This steel, excellently hardenable in both oil and air, is highly resistant to crack formation due to thermal fatigue and is not very sensitive to sudden temperature changes. It is also well formable at high temperatures and easily machinable when annealed to a soft state.

Steel 8Cr - Mo - V offers an advantageous combination of strength (even at high temperatures) and high toughness. Its undeniable advantage is also very good resistance to wear and impact.

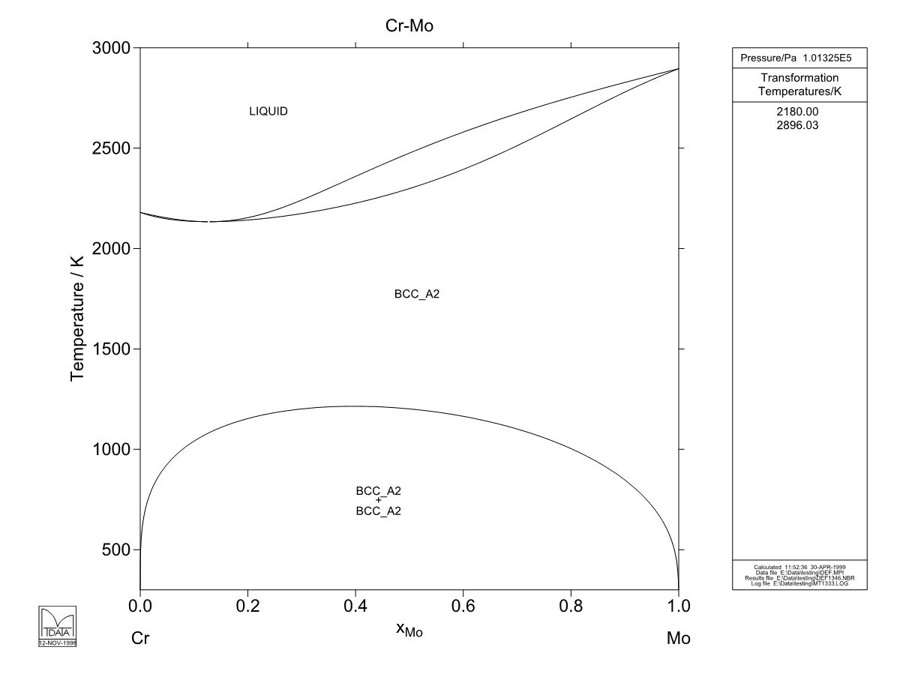

- Chromium - Cr adds hardness to classic steel, reduces elasticity, and increases strength (even at low temperatures) and chemical stability, generally increasing chemical resistance with chromium content. The chromium content is around 12-13% in stainless steels.

- Molybdenum - Mo has similar properties to chromium in the steel structure, but increases resistance of the steel to chlorides and acids, improves hardenability, and creep strength. The molybdenum content is around 0.2-0.3%.

The ratios of elements may vary depending on the application of the steel.

It is possible to add other chemical elements such as carbon, manganese, phosphorus, sulfur, and silicon.

This is a fine-grained version of steel with a homogeneous structure to ensure higher utility properties and significantly increased durability.

It is used for water-cooled molds for pressure casting of aluminum, zinc, and magnesium alloys, hot-forming tools, highly stressed dies, matrices, and mandrels. Also for hot extrusion of non-ferrous metals, trimming tools, and shears for hot cutting. Further possibility of making thinner cross-section walls while maintaining strength. However, a disadvantage is the lower elasticity and higher production costs. The higher weight compared to other types of steel cannot be overlooked either. Compared to other types of steel, however, this is steel with guaranteed properties at high temperatures.